New Donek D4 user learning curve

2 posters

Discuss the Donek Tools Drag Knife :: Donek Tools General Discussion Topics :: General Message Board

Page 1 of 1

New Donek D4 user learning curve

New Donek D4 user learning curve

I'm cutting craft foam in an attempt to learn how to effectively use my new D4 drag knife. I'm using VCarve Pro with the Dragknife gadget to generate my G-code and running it on an X-Carve CNC. My eventual goal is to cut leather.

I'm encountering a number of problems, some of which I've worked out the solution myself and others I'm still struggling with. The image below is my current set of problems;

I would appreciate any tips. I've watched (and will rewatch) the videos and they've helped tremendously, but I'd like to use the tool to it's fullest potential. There were worse problems when the image was smaller, so size may be an issue. I've experimented with the offset, but perhaps not enough.

Thanks!

--Tim

I'm encountering a number of problems, some of which I've worked out the solution myself and others I'm still struggling with. The image below is my current set of problems;

- I can't seem to avoid the curved tail when starting circles. I've done pretty well at avoiding them on the first circle in the toolpath, but some subsequent circles seem to get them.

- This model (of an alcohol molecule,) has an angled circle that I can't seem to get the knife to cut happily.

- those curly tails seem to happen a lot to me, even on a closed toolpath when direction changes.

I would appreciate any tips. I've watched (and will rewatch) the videos and they've helped tremendously, but I'd like to use the tool to it's fullest potential. There were worse problems when the image was smaller, so size may be an issue. I've experimented with the offset, but perhaps not enough.

Thanks!

--Tim

timdeagan- Posts : 5

Join date : 2017-03-06

Re: New Donek D4 user learning curve

Re: New Donek D4 user learning curve

I may be a year or so late to this board  but I'll document my learning curve in case it's useful to someone else.

but I'll document my learning curve in case it's useful to someone else.

After watching more of the videos I found the method to test the offset. It describes using the ShopBot CC command to execute a circle with a radius of the desired offset. Ideally this should cause the point of the blade to sit in the center of the circle (because that's how far it should be 'offset' from the turning point,) and the knife to spin in a perfect 360 degree rotation. I'm using a GRBL based CNC so I'll figure out a G-code equivalent to the ShopBot CC command and post it here.

I also purchased SheetCam last night after seeing that it has abilities that the (wonderful to have,) drag knife gadget for V-Carve doesn't.

I'd also gotten confused earlier, but straightened out now about the starting position of the blade. If I understand correctly , it should be 90 degrees to the direction of travel (I'd been orienting it to the direction of travel.)

Start points on the vectors should be in locations that would orient the blade (traveling in a normally CCW direction,) so that it is parallel to the X axis.

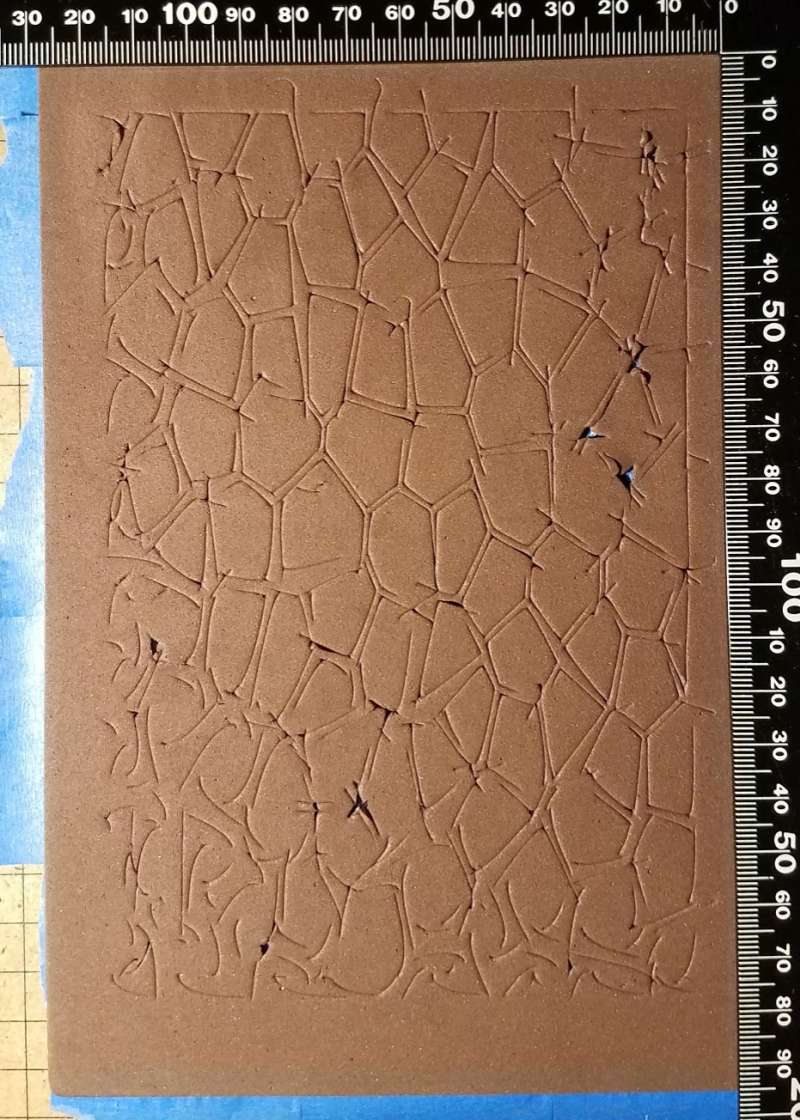

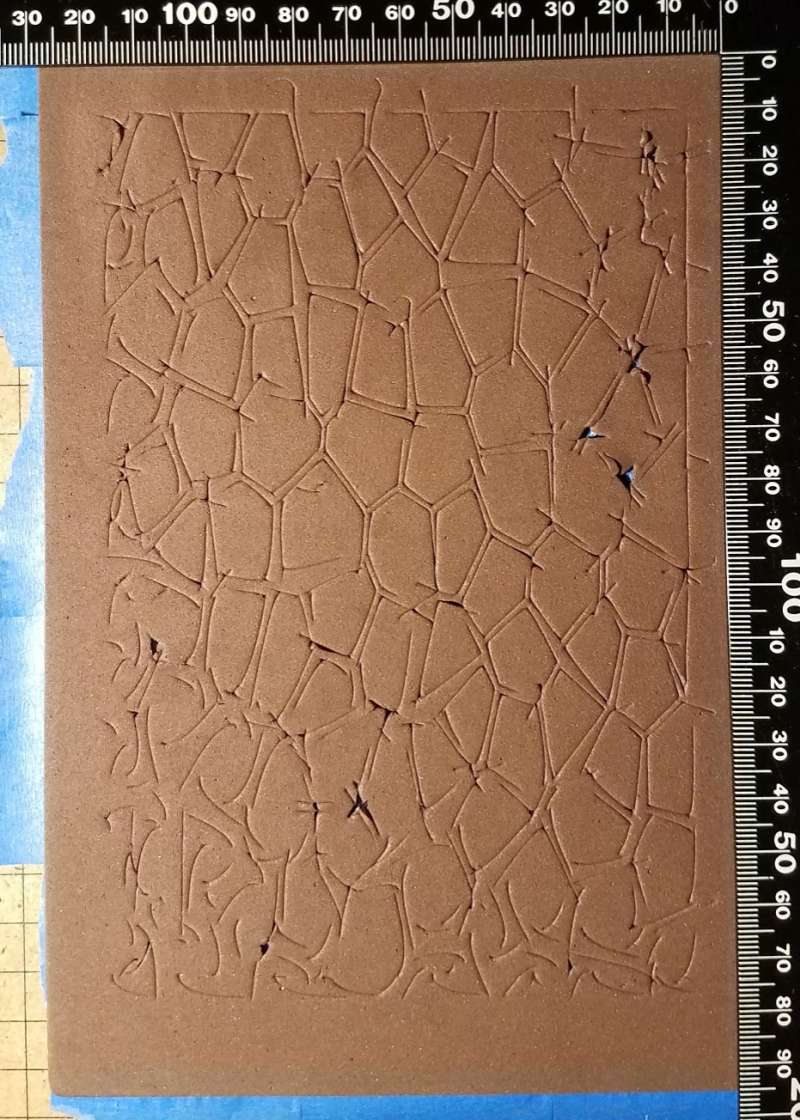

I also determined that I need a flycutting pass on my spoilboard. The difference from flat is very subtle, but it's enough that it impacts the blade's ability to hit it's swivel depth. On a different test last knife trying to cut a voronoi tile pattern, large areas were crud based on a gentle height difference. (see the lower left corner. Everything _should_ look like the section just above center to the right.)

After watching more of the videos I found the method to test the offset. It describes using the ShopBot CC command to execute a circle with a radius of the desired offset. Ideally this should cause the point of the blade to sit in the center of the circle (because that's how far it should be 'offset' from the turning point,) and the knife to spin in a perfect 360 degree rotation. I'm using a GRBL based CNC so I'll figure out a G-code equivalent to the ShopBot CC command and post it here.

I also purchased SheetCam last night after seeing that it has abilities that the (wonderful to have,) drag knife gadget for V-Carve doesn't.

I'd also gotten confused earlier, but straightened out now about the starting position of the blade. If I understand correctly , it should be 90 degrees to the direction of travel (I'd been orienting it to the direction of travel.)

Start points on the vectors should be in locations that would orient the blade (traveling in a normally CCW direction,) so that it is parallel to the X axis.

I also determined that I need a flycutting pass on my spoilboard. The difference from flat is very subtle, but it's enough that it impacts the blade's ability to hit it's swivel depth. On a different test last knife trying to cut a voronoi tile pattern, large areas were crud based on a gentle height difference. (see the lower left corner. Everything _should_ look like the section just above center to the right.)

timdeagan- Posts : 5

Join date : 2017-03-06

Re: New Donek D4 user learning curve

Re: New Donek D4 user learning curve

- Code:

G90

G20

G17

G1 X1.00

G3 I.160 P10

1st line sets up absolute positioning

2nd line tells the system to use inches

3rd line defines the plane in use to be the XY plane

4th line moves the tool to X1 (change to X value to the location desired for the test)

5th line tells the system to move the tool 10 times in a CCW circle with radius 0.16", the circle starting at the 3:00 position (change the I value to the offset you want to test)

This assumes that you have zero'd the blade in the Z axis. The test needs the point of the blade to touch something so that the tool can rotate around it.

I believe it also requires initializing the tool position by making the last move prior to the circle be in the X+ direction (4th line.) This leaves the blade tip trailing the tool with both parallel to the X axis. When the tool begins its CCW rotation, it would then do so around the tip.

I'll test this tonight and document my findings.

EDIT - After testing, this has numerous problems. For one thing, the G3 command is very picky I started getting it to stop throwing errors when I changed to: g3 x0 y0 i0.160 j0 f8

While that worked in my simulator, on my GRBL based XCarve it didn't cut a circle, it cut a quarter circle CW arc followed by a negative Y travel (which I had to stop.) I'll respond with more adventures (unless some kind soul wants to cut to the chase and save me from my mistakes

Last edited by timdeagan on Wed Mar 08, 2017 7:27 am; edited 2 times in total (Reason for editing : Incorrect Gcode)

timdeagan- Posts : 5

Join date : 2017-03-06

4th axis for cutting compound curves

4th axis for cutting compound curves

I am a model ship builder creating ships in wood. I cut vertical frames for the hull from 4mm ply. The outer edges of these profiles, to which the horizontal planks are fixed, are beveled, and the bevels change in angle throughout their length, so that they meet the curve of the planks squarely. To do this accurately by hand is tedious and time consuming. Another way to achieve this (I think,) is to use a 4th axis CNC setup. I am an almost complete newbie, but here goes.

I am considering using a Stepcraft CNC with a 4th axis device controlling a tilting table and a Donek knife to reduce dust.

I can't attach my drawing of a simplified setup, but could send it on request.

Creating CAD drawings of the vertical frames and their bevels is reasonably straightforward. However, finding the appropriate CNC software and programming it is my current problem.

There is a direct relationship between x, y, and z locations of the blade tip and the relevant angle, giving the correct angle and depth of cut at any point on the profile, and hopefully creating a smooth transition between information points. The curves will be Béziers curves.

I would appreciate your opinions on this approach, (which can be modified to suit any compound curves), as well as any wisdom on suitable software.

Thanks.

BillQB2213- Posts : 1

Join date : 2017-12-19

Similar topics

Similar topics» For Sale Donek D3

» What is the Donek Tools Swivel Program

» Donek Tools Project show and tell

» Donek Dragknife, V Carve Pro, and Shopbot Desktop

» using donek tools in 3 axis cnc machine router

» What is the Donek Tools Swivel Program

» Donek Tools Project show and tell

» Donek Dragknife, V Carve Pro, and Shopbot Desktop

» using donek tools in 3 axis cnc machine router

Discuss the Donek Tools Drag Knife :: Donek Tools General Discussion Topics :: General Message Board

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|